Basically , all I do is place my template at each section, which I marked from the previous step, all around the blade. I align each template on the front side (leading) edge and mark the airfoil shape as it would touch that blade station. See below, C is marked at C, and D is marked at D. Where the most forward edge touches the line is the leading edge. I do this for every section along the blade. I then draw a line from peak to peak. This line is the leading edge line. And will guide you where NOT to cut. I repeat this is the line in which you do NOT want to remove material. You want to remove material above and below it, but that line is suppose to be the most forward part of the blade, and will never be cut. Make sense? I hope so, or your in trouble. I repeat this with the back edge (trailing edge).

FYI, leading and trailing edge is an Aerodynamics term, which as you may have guessed, is how the airfoil 'sees' the air. Leading edge being the first part of the airfoil or wing to feel the air, and the trailing edge is the last. See being a nerd is cool.

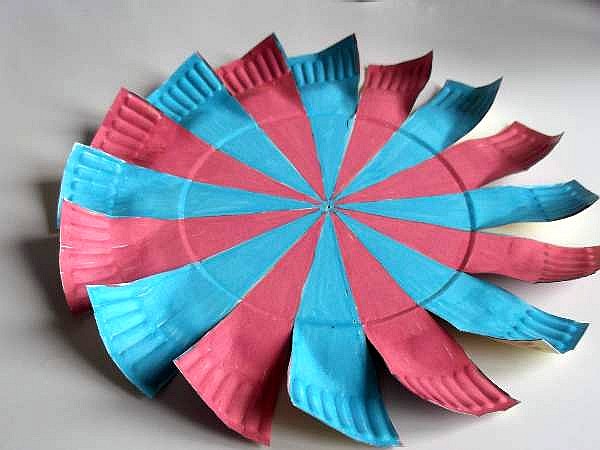

Paper Wind Turbine Blades Template

Basically , all I do is place my template at each section, which I marked from the previous step, all around the blade. I align each template on the front side (leading) edge and mark the airfoil shape as it would touch that blade station. See below, C is marked at C, and D is marked at D. Where the most forward edge touches the line is the leading edge. I do this for every section along the blade. I then draw a line from peak to peak. This line is the leading edge line. And will guide you where NOT to cut. I repeat this is the line in which you do NOT want to remove material. You want to remove material above and below it, but that line is suppose to be the most forward part of the blade, and will never be cut. Make sense? I hope so, or your in trouble. I repeat this with the back edge (trailing edge).

FYI, leading and trailing edge is an Aerodynamics term, which as you may have guessed, is how the airfoil 'sees' the air. Leading edge being the first part of the airfoil or wing to feel the air, and the trailing edge is the last. See being a nerd is cool.

- Blade engineering and design is one of the most complicated and important aspects of modern wind turbine technology. Engineers strive to design blades that extract as much energy from the wind as possible throughout a range of wind speeds and gusts, yet are still durable, quiet and cheap. A variety of ideas for building turbines and teacher handouts are included in this document and at the Web.

- Wind Turbine blade design and construction using built up software designed 'slices'. Build the prototype of a wind turbine blade with fiber glass, cardboard, software, tools and affordable or free materials.

Wind Turbine Blade Template

WIND TURBINE DESIGN AND TESTING ACTIVITY: WIND TURBINE DESIGN AND TESTING. 1 cork, tape, toothpicks, and stiff paper for the blades. Advise students that they can cut blades into the shape of the template or another shape of their choosing. Demonstrate cutting out a. Because the wind turbine blades and rotors are very large (some modern.